- Your shopping cart is empty!

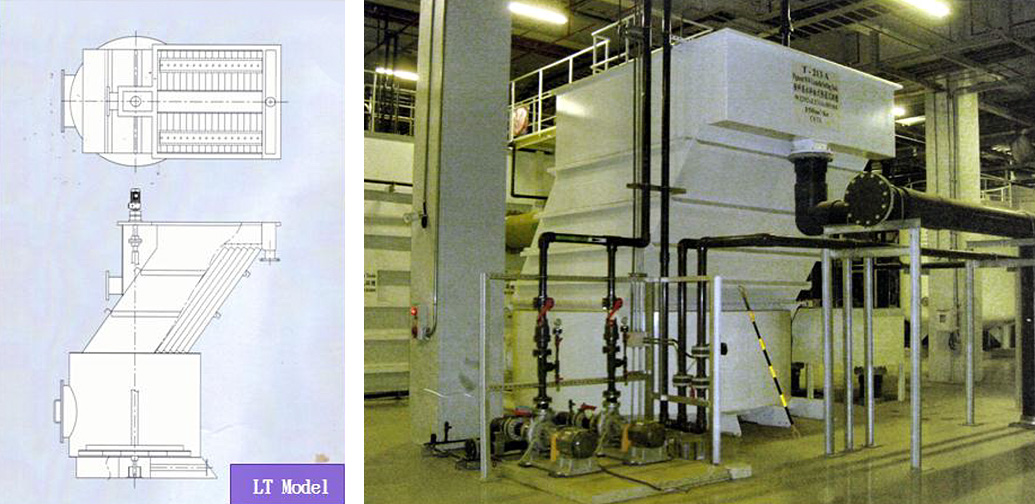

LAMELLA PLATE CLARIFIER

Water Purifying Equipment for Water & Wastewater

Introduction

Conventional settling reactor always required large surface loading and retention time. Our Lamella Plate Clarifier has overcome all the design weakness mentions above, that we have smaller foot print and operation time, and yet promising outlet treate water

Features

>> High efficiency of sludge–water separation, required surface area is only 30% foot print of conventional system, even can up to 10% max.

>> Inclined plate is used in the system, which no mud blocking cases.

>> Simple cleaning & maintenance

>> In-house fabrication

>> Fast delivery.

>> Easy to operate, save time.

>> Less manpower required.

Specification

| Model | Dimension L*W*H, mm |

Settling Surface Area, m² |

Scarping Motor Power, kW |

Treated Capacity, m³/hr |

Operating Weight, Kg |

| LT-12 | 2550*1600*3050 | 12 | 0.18 | 6- 12 | 6,620 |

| LT-25 | 3150*1850*3750 | 25 | 0.18 | 12.5- 25 | 9,750 |

| LT-40 | 3550*2100*4150 | 40 | 0.25 | 20- 40 | 17,100 |

| LT-60 | 4000*2550*4450 | 60 | 0.25 | 30- 60 | 19,850 |

| LT-80 | 4350*2900*4400 | 80 | 0.37 | 40- 80 | 26,540 |

| LT-100 | 4600*3200*4600 | 100 | 0.37 | 50- 100 | 31,400 |

| LT-125 | 4950*3200*5100 | 125 | 0.55 | 62-125 | 40,950 |

| LT-150 | 5250*3550*5300 | 150 | 0.55 | 75- 150 | 44,850 |

| LT-190 | 5750*4000*5300 | 190 | 0.75 | 95- 190 | 50,950 |

Note:

Surface loading rate is varied for different application, which is base on treated water characteristic (0.5-0.7 best for biological sludge, 0.7-1.0 best for chemical treatment sludge)